SQL Production

SQL Production - Manufacturing Process Planning (MRP) & Costing Control

SQL Production allows real time sync with inventory systems. Massive production is more visible to access the actual efficiency and productivity from each production line. With the precision of production data in the system will assist the costing calculation, cost variances, work in progress control and materials planning.

Manufacturing reports include:

- BOM Trees

- BOM Material Usage

- BOM Planner

- BOM Assembly Detail Listing

- Outstanding Job Order Listing with materials shortage summary

- BOM Wastage

- Work in Progress Report

- Stock Assembly-JO vs AS Variance

Recipes Master

Bill of Material (BOM) is a comprehensive inventory of the raw materials, parts, components or sub-assembly required to manufacture/assemble a product. Recall recipes to generate Job Order and plan the materials availability daily or weekly. Comparison with a standard and actual for cost and qty delivered a variance report to assist QC in making decisions.

Product Costing

Cost of manufacturing can be obtained from the bill of materials (BOM) in the SQL Production package. Actual material cost can be pulled from the Purchase Good Received module. In addition the landing cost can be absorbed as part of the materials purchase cost in the BOM. Cost reports are recorded for the assembly items. More cost types are user definable in the BOM such as labour, machine and overhead cost.

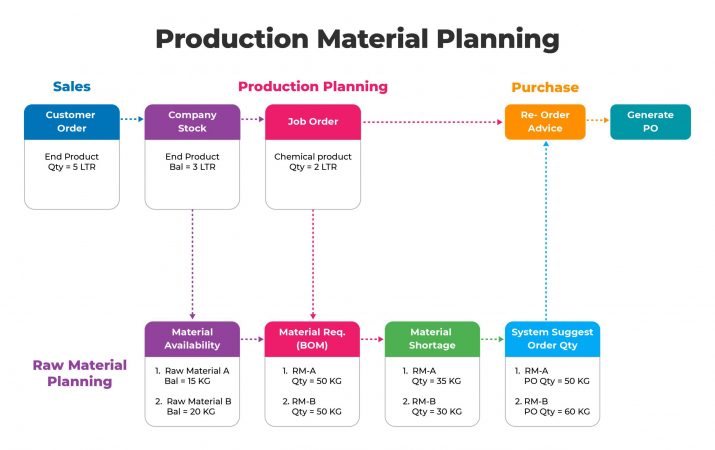

Production Materials Planning

Materials consumption planning is based on the customer PO by converting into Job Order to work out the total materials requirements. Reorder advice based on hand material stock plus outstanding PO and JO compared with the different reorder level for each materials stock. It will advise purchasers to plan the next purchase and delivery date before the materials stock has run out of stock. Quick generate PO based on reorder advise result.

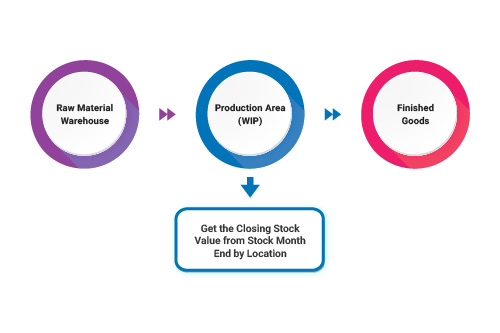

Work in Progress Control

Materials transfer into the production warehouse. Materials which is not consumed during a month will classified as Work-in Progress.

Traceability by Batch Production

Reduce the time to trace out the defective manufactured items that were returned by the customer from delivery order till production assembly where details of production information are recorded like materials usage, machine, etc. Add-on the batch module can record the manufacture date and expiry date for barcode label printing.

Benefits Of Using SQL Production MRP

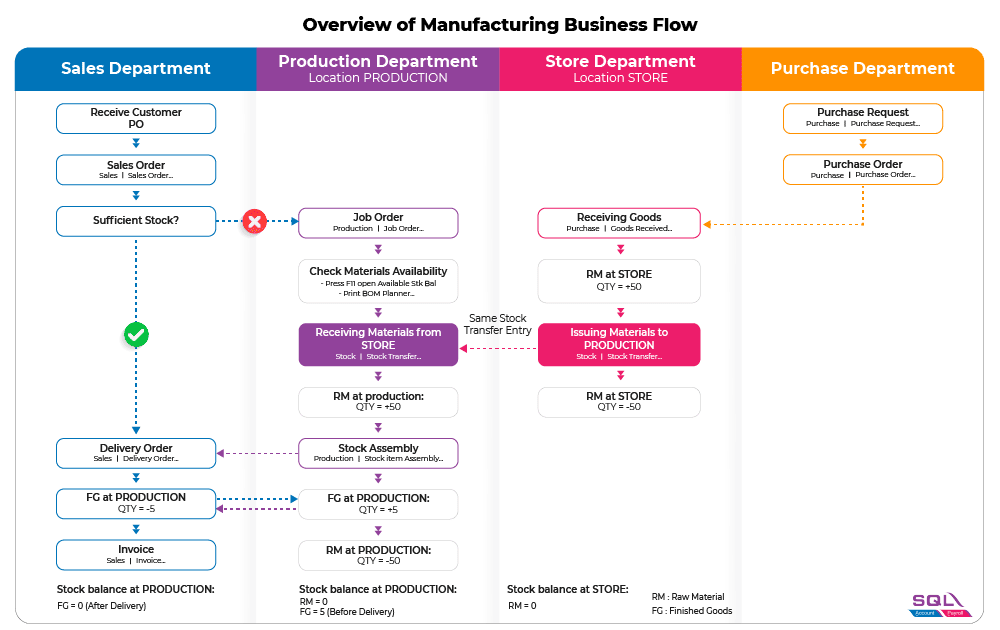

Visualise the stock data which has been shared from each department to increase accuracy and speed up decision making

Sales coordinator can update customer order and sync the sales order into Job Order for production to plan. System will auto calculate materials required based on the recipes and at the same time check the materials availability to allow production to carry on to meet the customer expected delivery date.

With the real time stock data from other departments, the purchaser is able to retrieve it to plan the materials to order from the supplier at the expected to be received date.

Minimise the shortage of materials case

System capable to analyse the materials required based on the production plan or customer orders delivery date.

Reduce unseen material losses

A good planning system should provide the real time stock data to avoid unnecessary loss of stocks due to over stock kept and expired.

Optimize the stock level as possible

A good planning system should provide the real time stock data to avoid unnecessary loss of stocks due to over stock kept and expired.